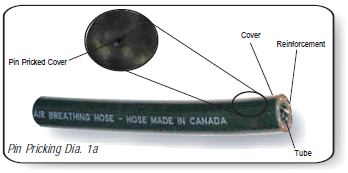

Pin-Pricked Hose Cover: Pin-pricking a hose cover permits trapped gases or vapours to escape from the hose carcass. Steam, air, and other gaseous products can permeate (pass slowly) through the tube and will build up in the reinforcement area - so the manufacturer must “pin-prick” the cover on certain hoses (see diagram 1a). This process is performed by a wheel that passes along the hose when it is pulled from the mandrel, pricking the cover in a series of uniform punctures that stop at the layer of reinforcement. Pin-pricks are often mistaken for “holes” in the cover of a brand new hose. Although a pin-prick should never noticeably leak or weep product from the hose, they are visible and normal. Without the pin-pricks, bubbles or blisters would start to appear in the cover of the hose. In the very rare instance of a manufacturer defect, the pin-pricks may go too deep (or too shallow) into the hose carcass (due to wall thickness fluctuations) and thereby physically leak or bubble.