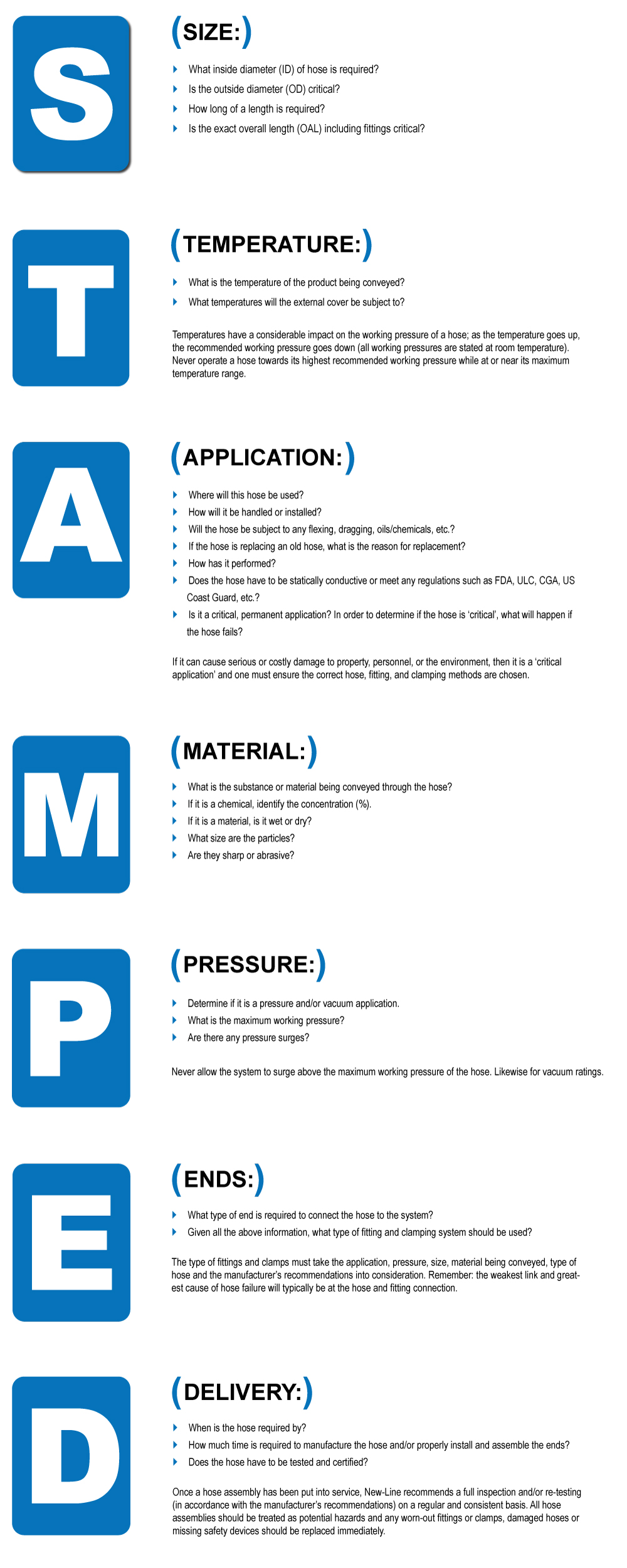

S.T.A.M.P.E.D. Hose Selection Guide

The acronym “STAMPED” will help in the proper selection of hose and/or fittings to reduce the chance of a failure from a misapplication. Serious damage and/or injury may occur if a hose or fitting is used in an application other than what it is designed for. It must also be noted that hose will degrade over time and is not designed for permanent piping applications, especially when it will not be subject to routine testing and inspection. These simple questions can greatly reduce the chance of a problem and help increase the useful life.

Can't find the information you are looking for? Contact our Sales Team for more assistance.