Hose is a critical yet often overlooked link in most transfer applications. A hose or coupling failure may result in bodily injury, property damage, and/or a significant loss of the product being conveyed.

Tips - Dos

• Know the limits of the hose, fittings, and clamps (rated working pressure of all components, temperature range, fluid compatibility, etc.) and always refer to installation instructions, clamping procedures, and grounding requirements where static buildup may occur.

• Request quality products and always consider “what will happen in the event of a failure”, because hose and fittings will indeed fail over time. If a failure would cause significant problems, injuries, or damage then special caution needs to be taken during selection.

• Store hose in a cool, dark, clean place where it will not be subject to any kinking, abuse, heat, humidity, ozone, and weathering.

• Drain and rinse hose after each use.

• Handle with reasonable care and ensure the hose does not kink at or near the fittings.

• Use pressure relief valves to control pressure surges which can shorten the life of the hose.

• Regularly and consistently inspect the hose for kinks, bulges, leakage, abrasion, and any gouges which expose the reinforcement - these may result in hose failure and should be removed from service.

• Regularly and consistently inspect the fittings for leakage, slippage, loose parts, corrosion, or any other noticeable deformities.

Tips - Don’ts

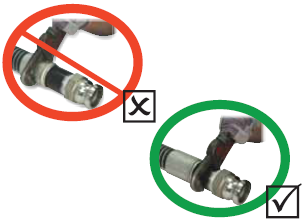

• Don’t allow a hose to kink near the fittings as the barb could cut the tube and lead to a failure (usually near the actual kink).

• Don’t use a hose at or near its maximum working pressure, especially while at its upper temperature range.

• Don’t drag over sharp or abrasive surfaces (unless specifically designed for that service) or tow/pull a hose by its ends.

• Don’t subject a hose to mechanical forces such hanging or supporting equipment/hard piping - and do not tug or pull on a hose.

• Don’t use hose in permanent, non-visible applications where it cannot be tested and inspected on a regular basis (hose is not piping).

• Don’t kink or crush a hardwall, non-collapsible hose (unless specifically designed for that service).

• Don’t store near any sources of heat, direct sunlight, and near electrical equipment, motors, welders or other sources of ozone.

• Don’t allow petroleum or chemicals to come into contact with the hose unless it is specifically designed for such service.

• Don’t substitute hose types unless recommended by the manufacturer and do not interchange different brands of hydraulic hose, crimp couplings, and crimp machines as it will result in a non-conforming or non-engineered system.

• Don’t allow the system to surge above the recommended working pressure of the hose.

• Don’t allow the hose to twist during installation; allow it to bend naturally.

• Don’t use a pipe wrench on a crimp sleeve or ferrule when installing threaded adapters.